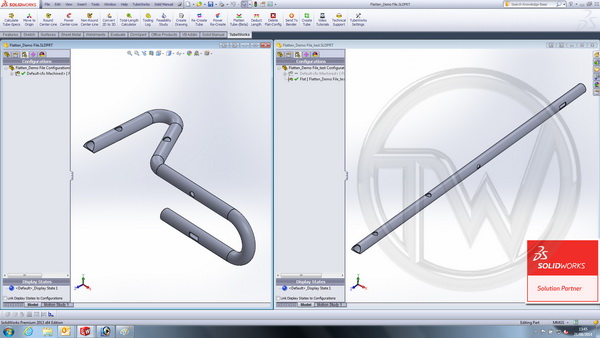

Lubricants, Coolants, Metalworking FluidsĪ new version of the TubeWorks tube bending CAD/CAM software from Unison Ltd (Scarborough, UK) now provides tubular metal fabricators with powerful pre-production tools for laser cutting as well as tube bending.Computerized Maintenance Management Systems.Abrasives, Belts, Brushes, Grinding Wheels.As well as offering a smart solution for metal fabricators seeking to accelerate their request-for-quotation procedures, the software will help companies with in-house bending machines to reduce design-to-manufacturing times. "TubeWorks will provide our customers with an enormous competitive advantage and is an important addition to our growing portfolio of software tools. "Automating the extraction of manufacturing data from CAD files helps bending machine users to create production-ready programs much more quickly and efficiently," says Unison Managing Director Alan Pickering. TubeWorks is fully integrated into SolidWorks, making additional standalone solutions for generating manufacturing data unnecessary during the design, development, and production of tubular components. Unison has obtained exclusive worldwide sales for the TubeWorks add-in from developer 3DCompound. It can accommodate tube models with round, square, rectangular, oval, or flat-sided oval cross-sections. The software automatically extracts important manufacturing data such as tube specifications and CNC bending data, from both native SolidWorks models and common CAD file formats such as STEP, IGES, and Para Solid. Tube bending machine builder Unison has launched an innovative PC-based CADCAM solution, TubeWorks, for tubular metal fabricators who use SolidWorks, allowing them to accelerate order processing and pre-production development time from hours to minutes.

"Unison to Sell TubeWorks for SolidWorks Tube Bending"

0 kommentar(er)

0 kommentar(er)